Dutch floating structure specialist Solarduck has built a pilot 65 kW floating PV array that will be connected to a 10 kW electrolyzer to produce hydrogen bonded with a liquid organic hydrogen carrier. The system is relying on the company’s proprietary floating technology that resembles an offshore oil platform.

Dutch start-up Solarduck has unveiled the first demonstrator project relying on its floating structure technology for solar projects at offshore sites in estuaries, natural harbors and near-shore sites.

The first plant built with this technology is being deployed on inshore waters in the Waal (Rhine), the widest river of the Netherlands, near IJzendoorn, a village in the province of Gelderland.

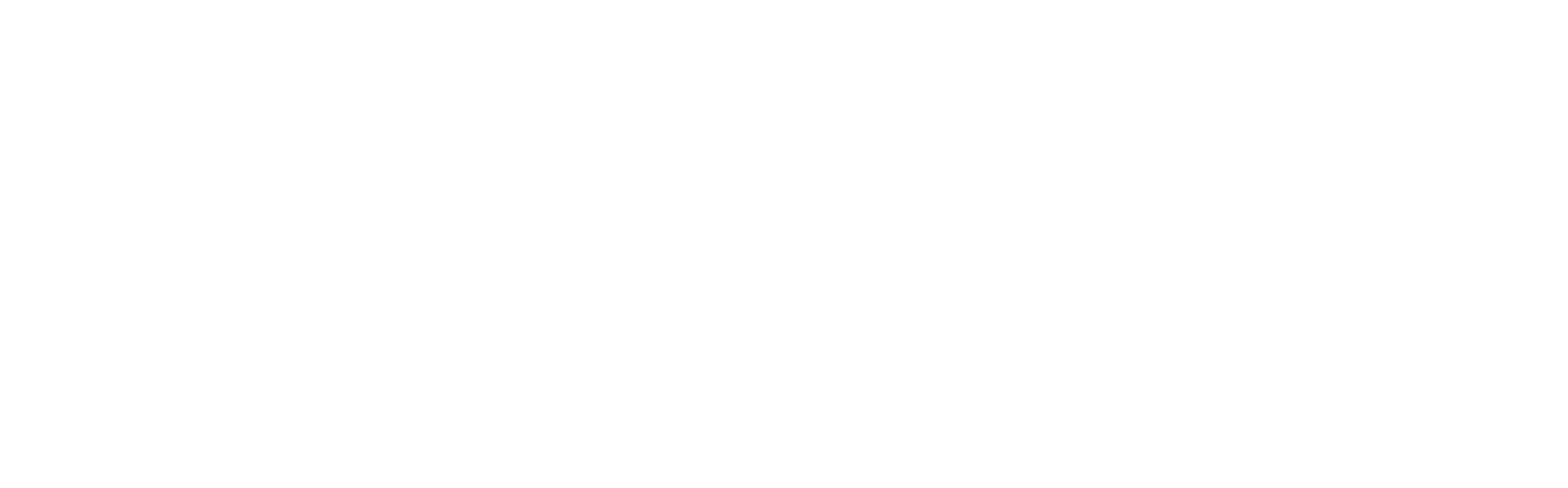

According to the company, the 65 kW floating array will be connected to a 10 kW electrolyzer that produces hydrogen. The pilot project is being developed with Dutch hydrogen company Voyex, which specializes in the production of hydrogen bonded with a liquid organic hydrogen carrier (LOHC), an oil-like liquid that serves as a binding agent.

“Soon we can start measuring the performance of the panels and the performance of the platform,” SolarDuck CTO Don Hoogendoorn told pv magazine. “Later this year it will be connected to the VOYEX demonstrator.”

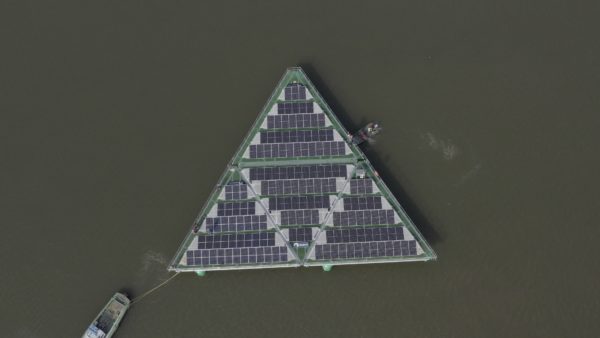

According to him, in the pilot, the four triangular structures were flexibly connected somewhat like a jigsaw puzzle, then towed upstream to the project location. “Based on the gained knowledge during the past months and the data coming from the demonstrator, we will start working on our second pilot project which will be put offshore in early 2022,” Hoogendoorn furher explained. “For that design, we focus on offshore performance validation and industrialization of the process.”

“We are targeting megacities and large companies in the Mediterranean, the Caribbean, South East Asia, and in general markets with high solar radiation in the global Sun Belt,” Burgers said in early March, in an interview with pv magazine.

The company’s basic floating structures are triangular in shape, measuring 16 x 16 x 16 meters, and can be flexibly connected together to form large megawatt-sized plants. These platforms allow the placement of PV modules more than three meters above the water surface. This particular configuration, according to the company, enables the use of conventional PV modules with high efficiencies without the need for specifically designed and more expensive products.

Chinese manufacturer Astronergy supplied the modules for the demonstrator project and Dutch materials specialist DSM provided its high-performance polyolefin Endurance backsheets, which have been fitted to the modules. The system was assembled at the facility of Dutch shipbuilding and engineering conglomerate Damen Shipyards, with Norsk Hydro Extrusion providing the aluminum extrusions.

The pilot project is being built at a cost of €1 million and was funded by the Province of Gelderland with €350,000.